Subscribe to our blog to keep up with our products and other industry information.

We are excited to announce a new version of Fusion. Please read the release notes for the details, but here are some of our favorite new features—including support for a new product which allows you to access Fusion data from anywhere in the world.

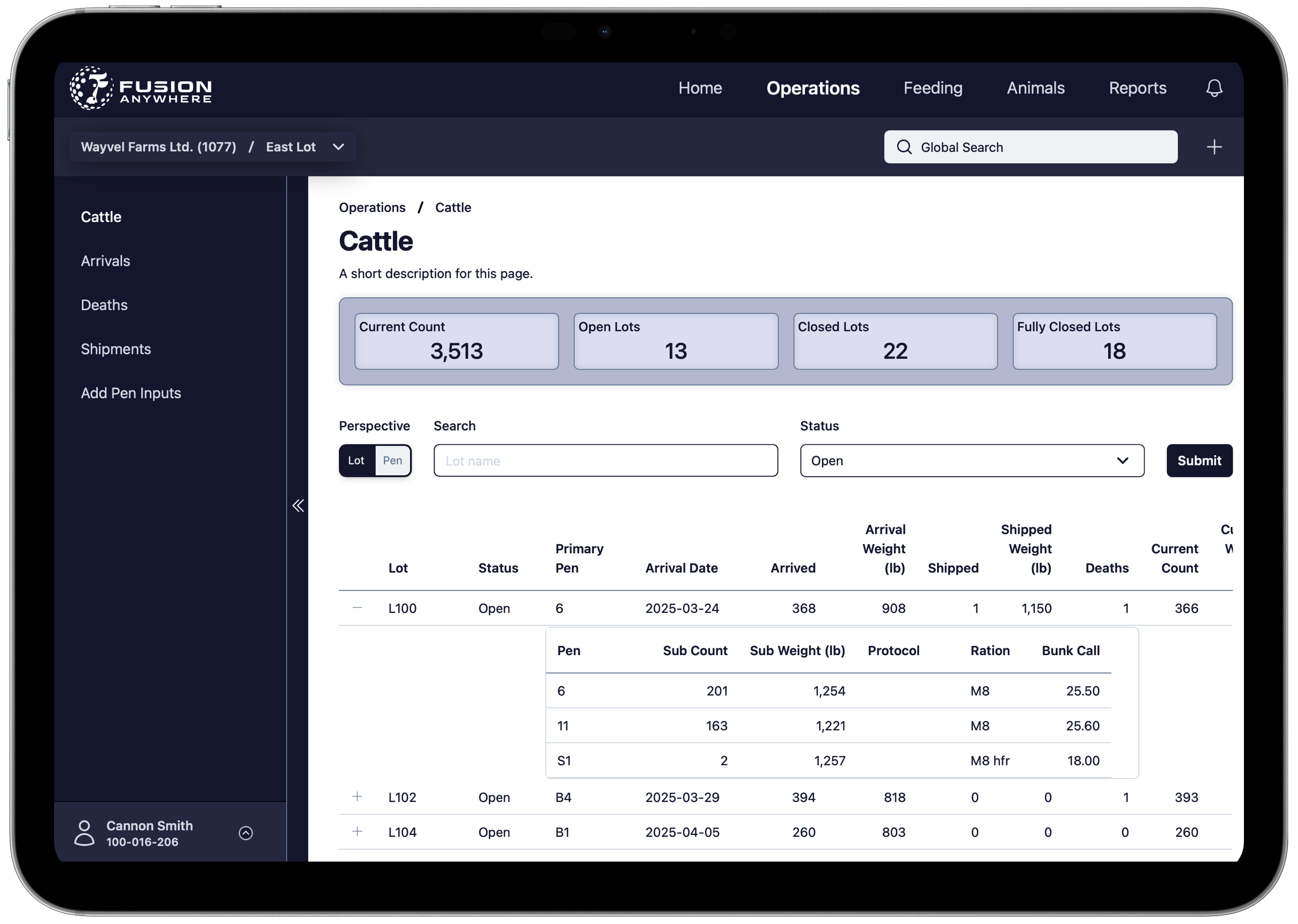

For years now, our most requested feature was for mobile access to Fusion. Starting with this version, Fusion is compatible with a new product we are offering called Fusion Anywhere.

Fusion Anywhere brings remote access to your local Fusion system without migrating your data to the cloud and without any technical setup. Your data stays right where it is: on-site, private, and under your control. At the same time, you can securely access it from anywhere in the world using just a web browser or mobile device. That means your employees, consultants, and partners stay connected while your system, data history, and security remain unchanged.

Fusion Anywhere is currently in beta. Please contact us if you are interested in testing it at your yard.

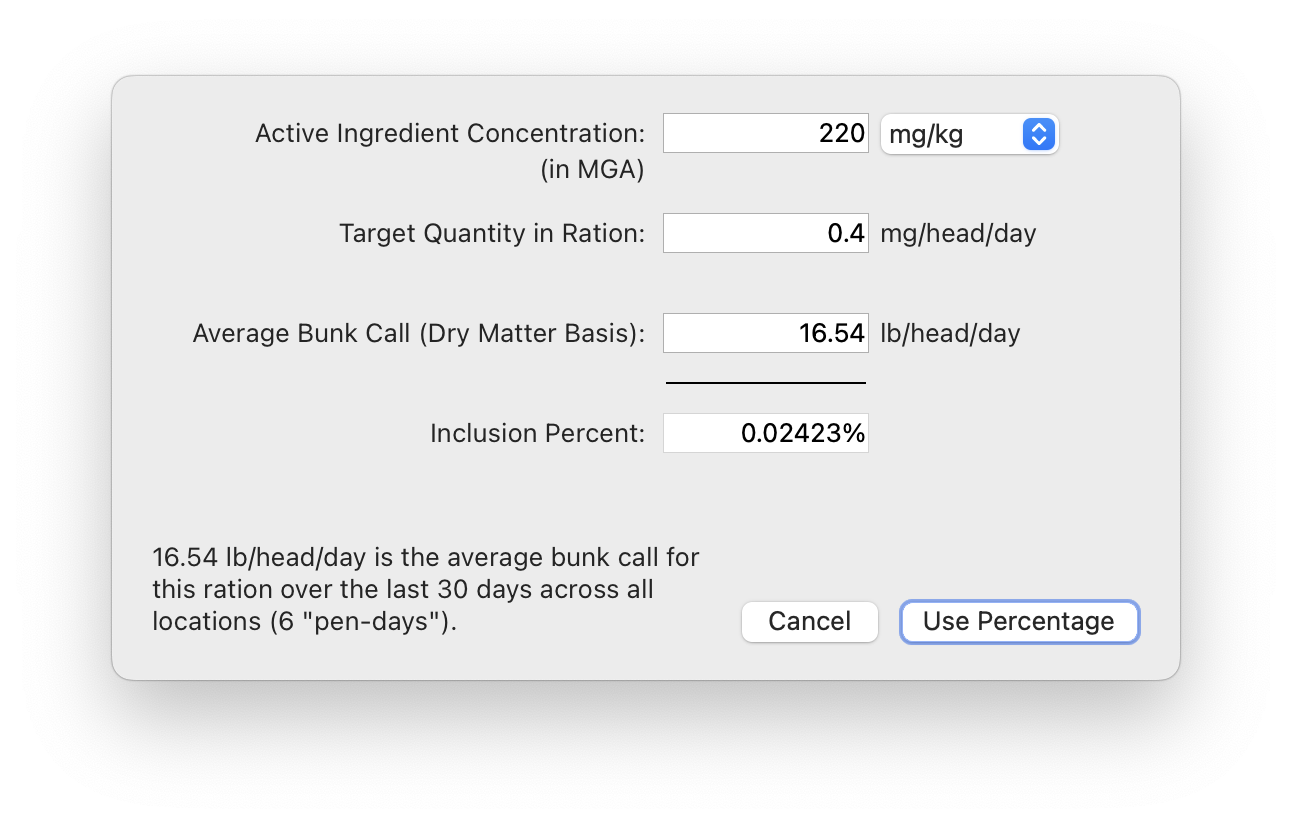

Do you worry about the accuracy of your ration formulations, especially the micro ingredients? In Fusion 4.5 we introduced a feature that allows you to define threshold value to ensure micro inclusion rates don't accidentally get out of whack. In Fusion 4.7 we are addressing another concern which is figuring out the inclusion percentage in the first place. New in the Ration Edit window is the Micro Inclusion Calculator. Click it when you add a micro ingredient and it will help you figure out the correct percentage.

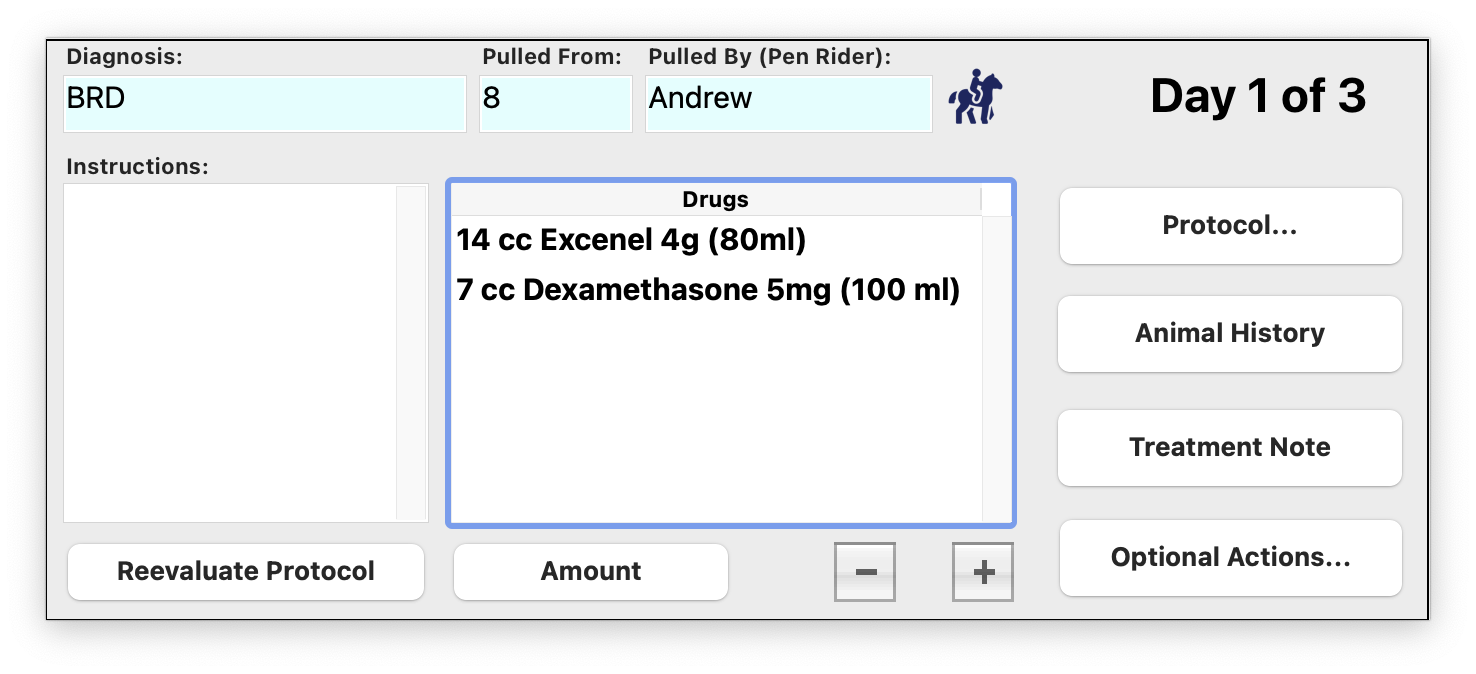

Have you wished you could keep track of who pulled an animal being treated? Now you can. When diagnosing an animal there is a new Pulled By (Pen Rider) field which can be used to enter the pen rider. Even better, if a Pen Rider is using Fusion Anywhere to view an animal's synopsis while in the pen, they'll be able to click a button on their phone to indicate they're pulling this animal while optionally adding information such as the symptoms they are seeing or the reasoning behind the pull. If the animal is treated on the same day, the pen rider's name will automatically be filled in and the information they entered is available to be read before making a diagnosis.

Do you have a remote display on your truck that can show alpha characters? If you do, you'll appreciate some additional options in the Remote Display settings window. With these new settings, you can have Fusion display the ingredient name on the remote display for a few seconds before returning back to displaying the weight each time a new ingredient is selected.

If you have a Comco micro machine, you may benefit from our new "Comco Databridge" integration which has a more robust communication system and supports Comco machines with integrated liquid and micro gravity dispensers. The old integration will continue to work, but we encourage switching to the new one when possible.

Again, check the release notes for more details. And we'll talk more about Fusion Anywhere in the near future. In the meantime, we hope you enjoy this version of Fusion!

We are happy to announce the release of another version of Fusion with some great new features and important bug fixes. Please read the release notes for the details, but here are some of our favorite new features.

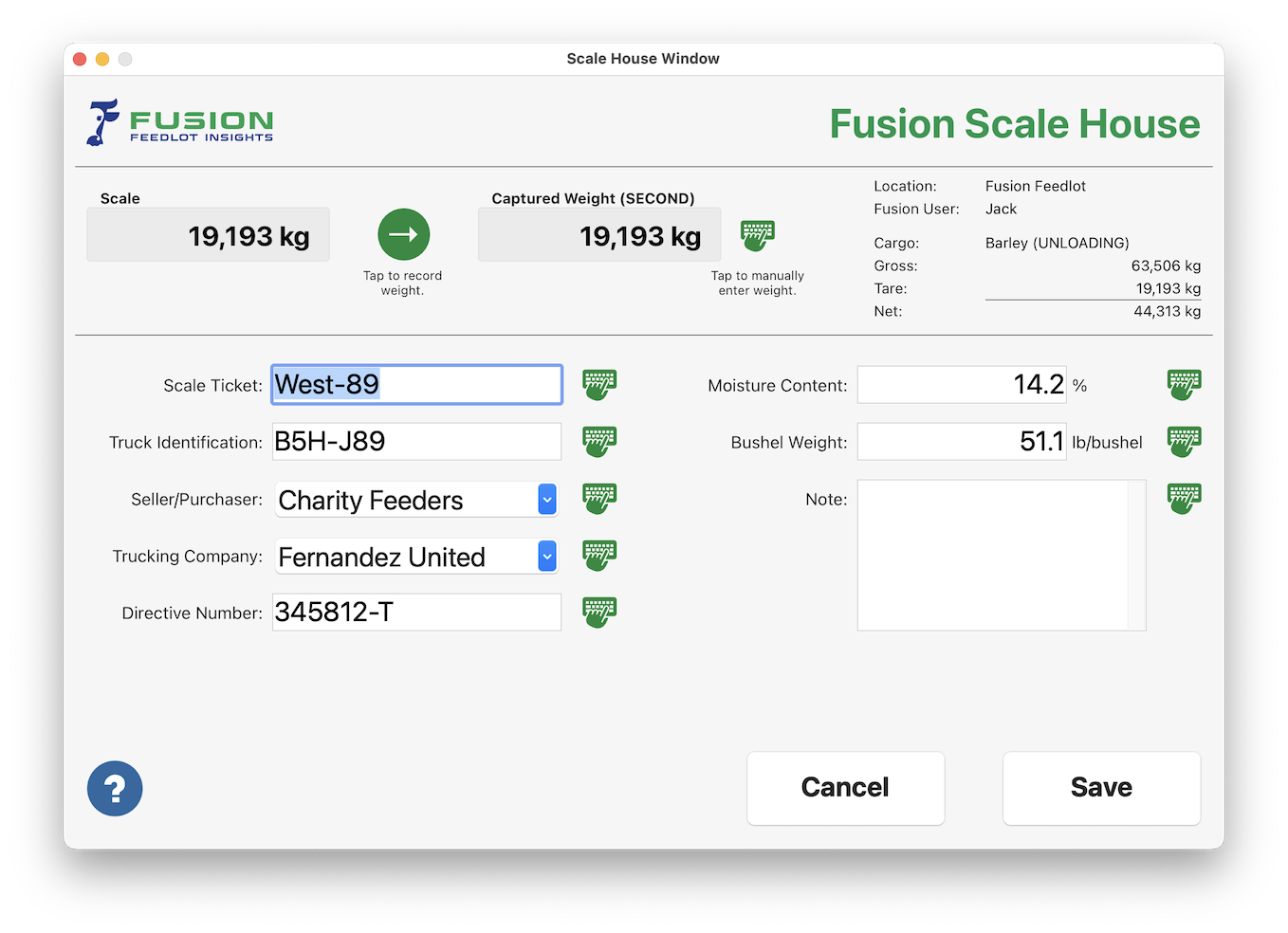

Have you ever wished Fusion could capture weights in your scale house? Well, now it can! Set up Fusion Client in your scale house and get your scale head connected to it. Then add a printer and you'll be good to go!

You can set the Scale House window to only work with your staff or to allow truckers to weigh in and out themselves. Back in the office, the scale house loads can be converted into scale tickets, in cohorts, out cohorts, or inventory offsets. A full audit trail for each load is maintained. Look for these new windows in the new Scale House menu under Fusion Commodity.

If it takes too long for data to load in the Daily Feed Detail window then you'll appreciate the work we've done in this window. Every section of this window should now load very fast, even in poor network situations. One tester saw the loads times for this window go from eight minutes to five seconds. No more waiting around!

The Daily Feed Detail window is great for looking at feed loading accuracy for individual loads, but perhaps you've been wishing for some insight into overall accuracy? That's what this report is for. Choose a date range and a location and you'll see what the overall loading accuracy is. You can even drill down per driver.

Hopefully you can use this report to identify areas where additional training or infrastructure changes will lead to greater accuracy in this key area.

The sync engine was completely rewritten to be much faster, especially at large feedlots with lots of trucks. And we completed the work to make Fusion OneDrive and DropBox compatible. There's a lot more so check out the full release notes here.

We hope you enjoy this version of Fusion!

P.S. Because of the deep changes made in this version, it will not be an automatic upgrade. Please contact us to schedule your upgrade and for further instructions.

We are excited to introduce you to Fusion 4.5 which has just been released. We encourage you to read the release notes for all the details, but here are some of our favorite new features.

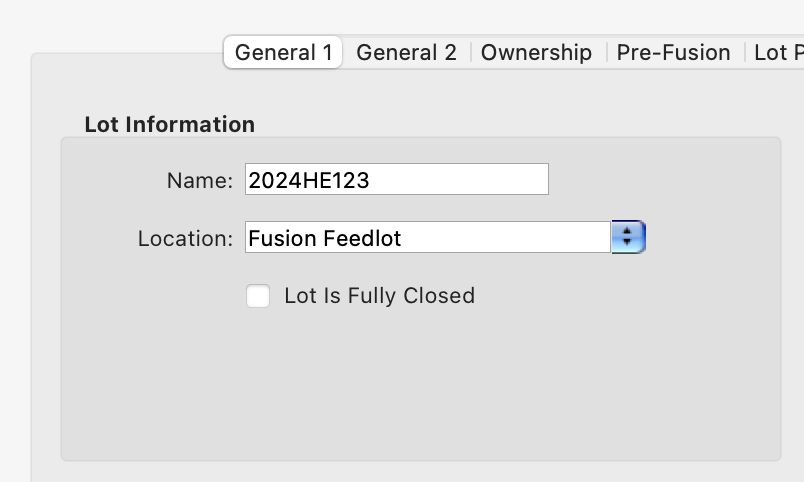

As you know, Fusion automatically sets a lot's status to closed when the last animal is sold and you can't manually change this status. Usually there is a period of time after the lot has closed when you are still working with the lot: entering billing information, managing invoices, printing closeouts, etc. Wouldn't it be nice if there was a way to distinguish lots that were still in this phase from those that you are completely finished with?

Well, now there is! We've introduced a new field which you can find in the Lot Edit window called Lot Is Fully Closed. This field starts off unchecked. After the lot has closed and you've finished working with it, check it off and you'll know you are completely finished with the lot.

This field is a new column in the Lot Center window so you can search with it. We also enhanced the Status popup in this window with a new option called "Fully Closed". Now when you set it to "Closed", lots that are closed but not fully closed will be shown and when you set it to "Fully Closed", lots that are both closed and marked as fully closed will be shown.

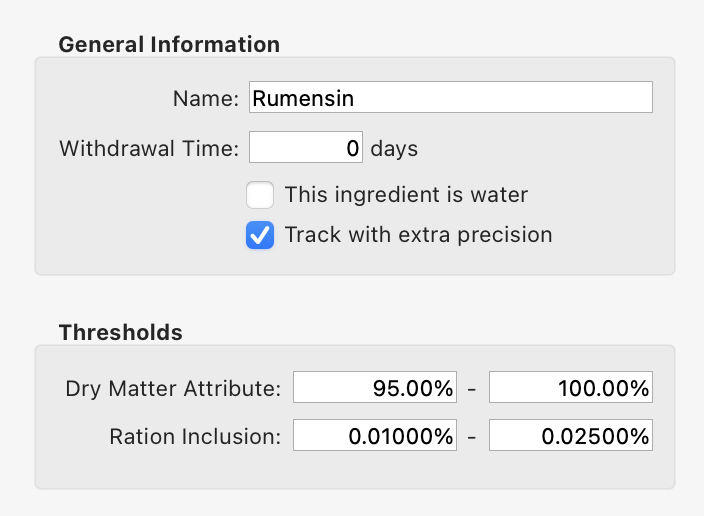

There can be confusing, if not devastating, effects if someone enters the wrong dry matter percentage for an ingredient attribute or the wrong inclusion percentage in a ration—especially for a micro ingredient. To alleviate these costly mistakes, we've introduced the ability to define thresholds for each ingredient.

Once defined, Fusion ensures that ingredient attributes and rations cannot be saved if a value outside the threshold is entered.

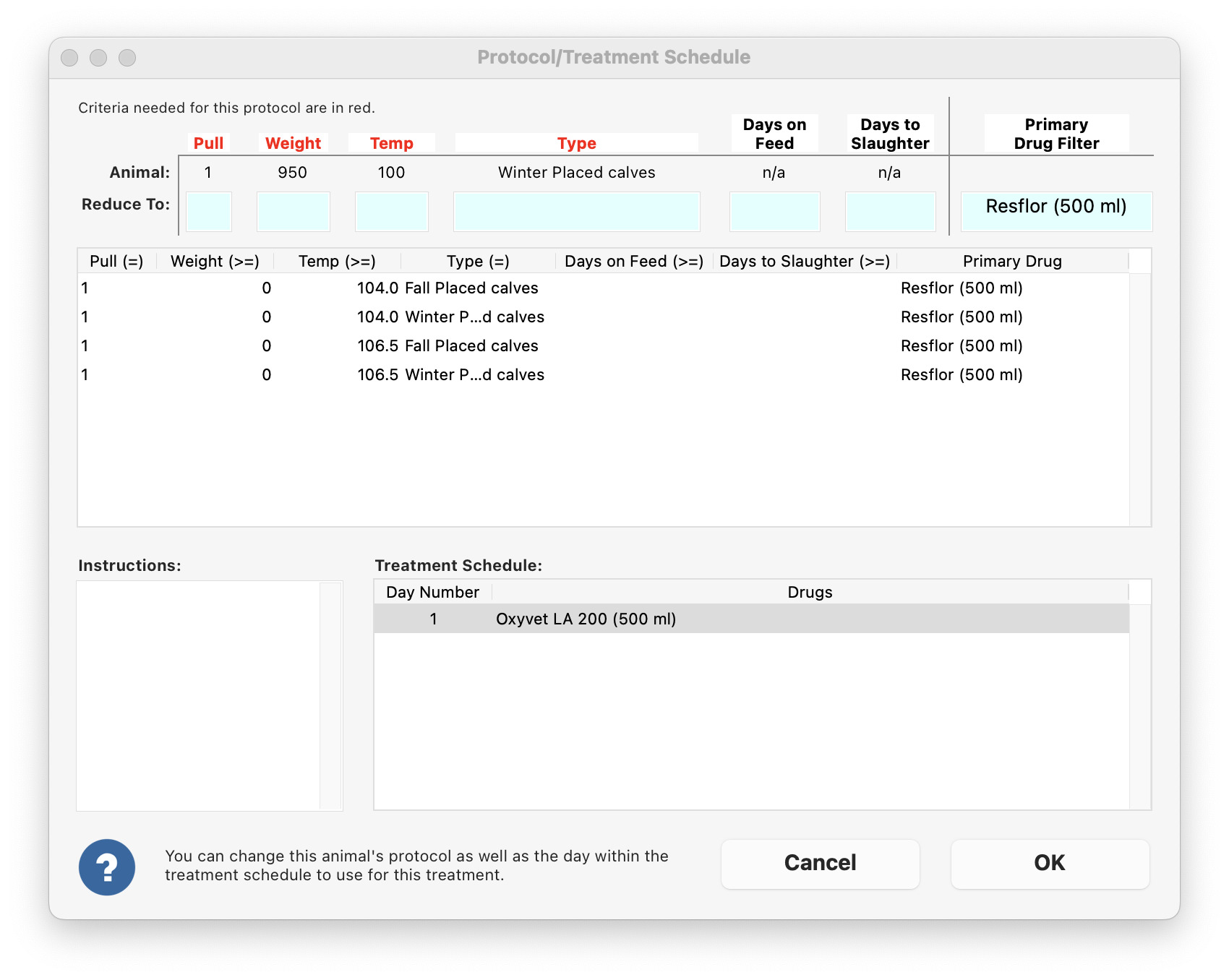

Have you ever found yourself scrolling through all the protocol variations while treating an animal, looking for the one which uses a particular drug? This just got a lot easier! The Protocol/Treatment Schedule window (this is the window you see when overriding a protocol while treating an animal) has an additional column labeled Primary Drug which shows the first drug listed for the first treatment date of each variation.

There is also a filter field above this column which you can use to quickly view just the variations with a particular primary drug. This small addition should be a great time-saver for these situations.

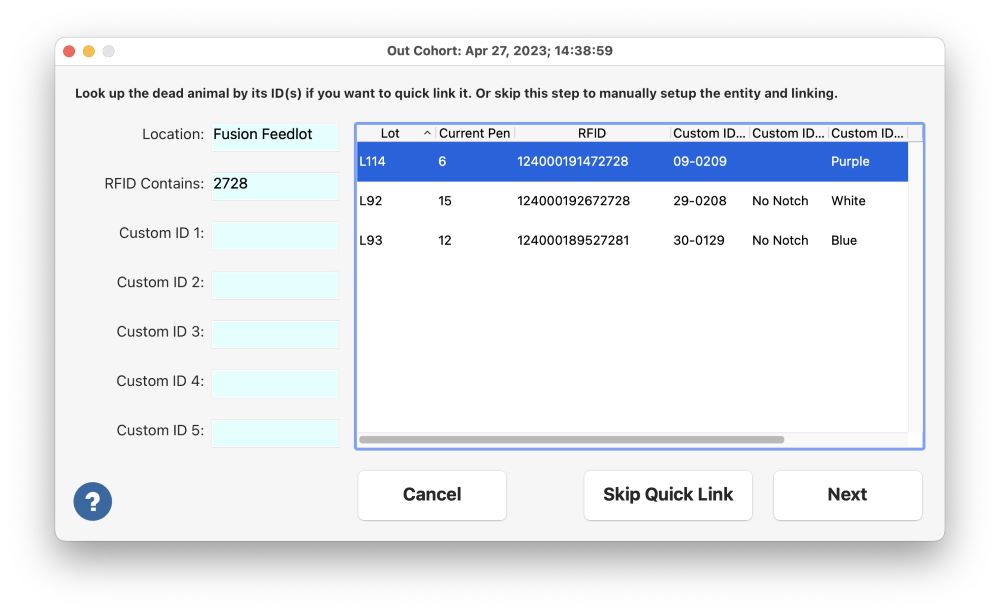

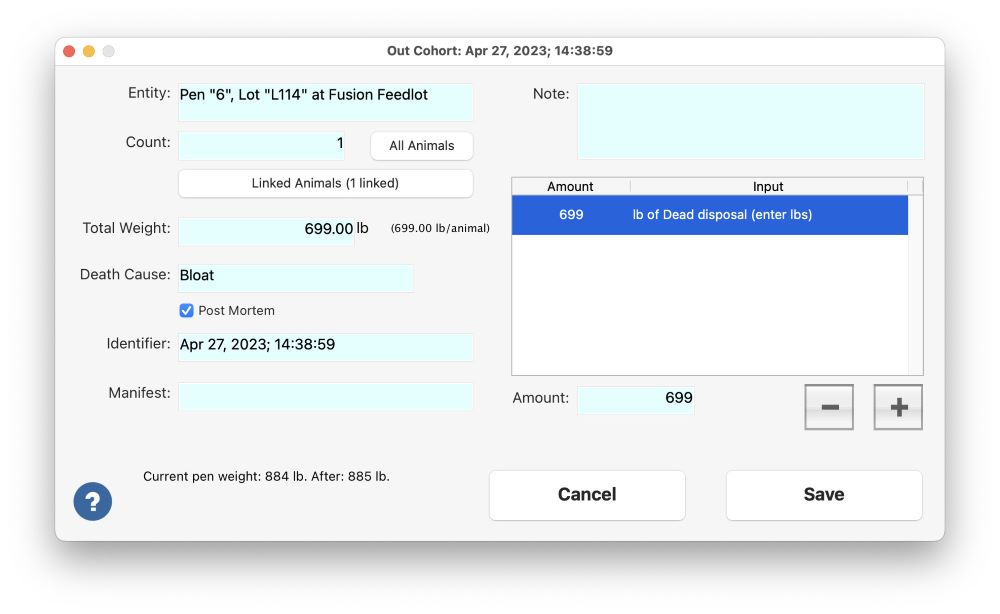

If your crew records deaths using the Simple New Death Out Cohort window, they know it can be a bit clunky to get the dead animal linked. This is because the window uses the same linking interface as other windows designed to link many animals. This upgrade smooths out the linking process by taking advantage of the fact that when you are recording a death, you are only linking one animal and you very likely to know the tag number.

Here's how it works: when the window first opens you get a chance to enter a tag number (even a partial RFID tag number works). Fusion shows a list of matching animals in a list. Just tap the correct one and Fusion will automatically link the animal and set up the entity in the next screen, saving you a lot of clicking!

We learned that some customers were not using this window to record deaths because it didn't allow you to record the associated inputs at the same time. So we redesigned the main part of this window to accommodate this. You can still enter them in the office, if desired.

There's a lot more. Once again, please check out the full release notes here.

We hope you enjoy this version of Fusion!

[In this post, Darryl Gibb explains how to include ingredients which are formulated based on quantity rather than concentration in a ration formulation within Fusion. Darryl has previously written an article titled "Switching to Dry Matter Based Feeding" and another titled "Fusion Feeding Protocols" which are also very useful.]

When a load of feed is made, all included ingredients make up a percentage of the total load. Yet some ingredients are specified to be added at a certain quantity (i.e. grams/head/day) instead of a concentration (i.e. a percentage). For example, MGA is cleared to be fed at 0.4 mg/head/day. Or, in another example, you may want to feed 1 gram of chlortetracycline (CTC) per head per day.

These values are easy for us to understand, but impossible to deliver. We feed pens of cattle, not individuals, so we really can’t deliver 1 gram of CTC to each animal. The best we can do is include the desired quantity in the average intake of the pen or ration. We also need to convert the 1 gram of CTC to the quantity of product being used.

Let’s assume you are using Chlor 100 which is 22% CTC, so you actually need to feed 1 ÷ 0.22 = 4.5 g of Chlor 100. If average dry matter intake is 15 pounds (6.8 kilograms), then you need to include 4.5 g of Chlor 100 ÷ 6.8 kg, or 0.066% Chlor 100 on a dry matter basis.

If the feeding rate of a pure product (i.e. yeast) specifies to feed x g/hd/d, then the concentration is simply x ÷ average intake. Remember to make the proper conversions so x and average intakes are in the same units.

Here is a spreadsheet which you can use to convert quantity based ingredients to a concentration basis: Quantity To Concentration.xlsx.